INTRODUCING THE WORLD’S FIRST ECO-FRIENDLY FOAM SPACER

EcoSpacer™ is produced with zero carbon, zero salt, and zero waste-water! This new spacer provides superior warm-edge performance for insulating glass units (IGU) with an industry best vapor barrier, with optimum gas barrier performance against moisture ingress or argon escape. Enjoy FS foam spacer savings of up to 50%, on your IGU fabrication lines.

CLEAN PRODUCT: Being silicone free, this flexible polyurethane foam spacer delivers a clean vapor barrier and fog-free performance.

TIME-SAVING: 1 hour of EcoSpacer™ production can feed 3 or more hours of automated IG line production.

RETURN ON INVESTMENT: A licensed EcoSpacer™ line can save money on spacer, packaging and disposal (through in-house turnaround and reel reuse) and shipping costs.

CUSTOMIZABLE: By only storing raw materials on-site, all spacer sizes are available as needed, from 5mm to 50mm.

ENERGY EFFICIENT: EcoSpacer™ production lines run on 220V, with low power consumption: saving energy and the environment.

EcoSpacer™ meets and exceeds ASTM E2190, EN1279 standards (IGCC/IGMA reviewed spacer listed).

NO SILICONE REQUIRED

Fog-Free & Cures In-Line (No Post Baking)

EcoSpacer™ features a flexible matrix of UV resistant thermoset polyurethane and 3A molecular sieve. Having fog-free performance by nature, it is silicone free, preventing contamination of vapor barrier or IGU. No volatiles to out-gas and requires no baking, with no chemical fog in the airspace and zero silicone contamination. Control your IGU quality (and durability in field) with this silicone-free and naturally fog-free foam spacer with the highest adsorption capacity. Also, offer better warranties against spacer displacement by being silicone free.

POWERFUL MULTI-LAYER BARRIER

Industry Standard Moisture and Gas Barrier

The 3A desiccant, due to our new manufacturing procedures, results in double the moisture pickup of other flexible spacers, and guaranteed adhesion with all insulating glass sealants.

Choose between acrylic PSA and an enhanced butyl PSA for EcoSpacer™ side adhesive. This allows for different choices of secondary sealant behind EcoSpacer™.

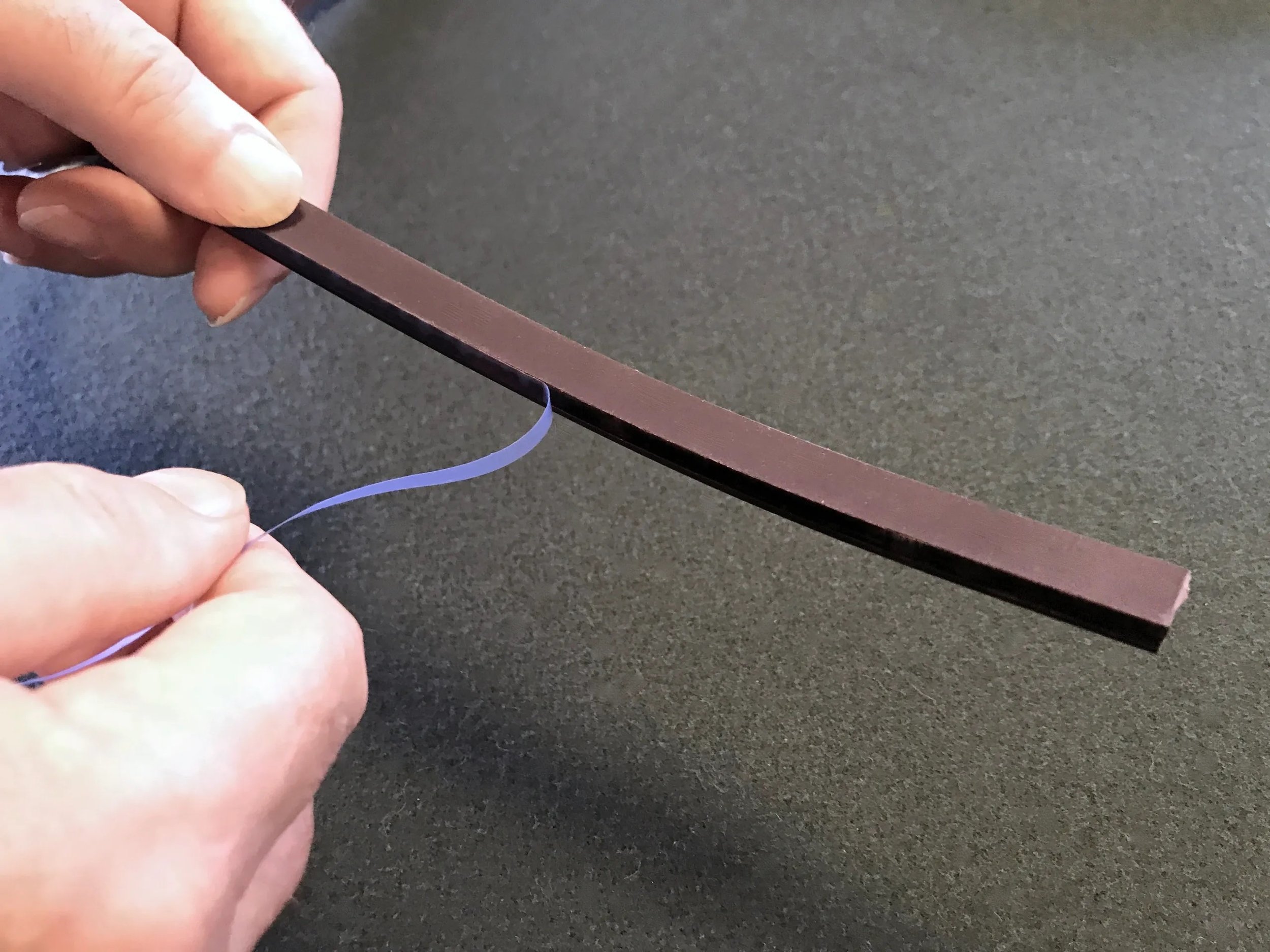

PRECISION CUTTING (5-50mm)

Zero Tolerance with Razor Accuracy

Make the spacer sizes, as they are required, in a just-in-time manner, a week, a day, or hours before needed with EcoSpacer’s™ industry best zero tolerance spacer sizing, from 5mm to 50mm. Spacer sizes being produced can be changed on the fly, without stopping the cutting line, and with very low scrap. Up to four different spacers and spacer sizes can be produced at the same time with razor accuracy, and near-zero tolerance on spacer width sizing. (Eliminates flexible spacer tolerance issues of up to +-5%).

FULLY AUTOMATED LINES

Make Your Own In-House Spacer With Ease

A push button start and stop production line for your spacer needs, whether running for two hours or twenty-four hours. EcoSpacer™ has been engineered for use on automated IGU production lines with robotic spacer application machines, as well as for manual spacer methods. Inhouse EcoSpacer™ production and its’ adhesive options make it suitable for both residential grade IGU as well as commercial IGU, all out of one spacer. One hour of running the EcoSpacer™ line produces enough flexible spacer for feeding three or four vertical robotic IGU lines.

ECOSPACER™ T AVAILABLE

T Spacer Variants Available (EcoT™)

Our T-shaped silicone-free spacers (EcoT™) are flexible, and are provided with an adhesive that is pressure-sensitive. Our T spacer is designed for efficient automated processing in-house.

SAVE TIME AND MONEY

Reduce Inventory Cost & Shipping Times

Inventory raw materials alone, good for making all your spacer size needs, rather than costly finished spacer in all necessary sizes. Reduce spacer inventory cost and shipping lead times.

+

Reach out today to learn more about EcoSpacer™!

The world’s first eco-friendly foam spacer produced with zero carbon, salt and waste-water!